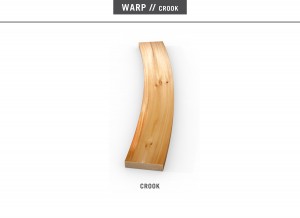

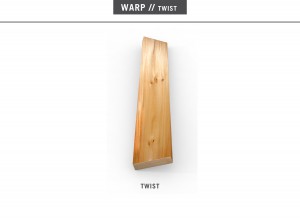

Compression wood is abnormal wood that forms on the underside of leaning and crooked coniferous trees. Compression wood is characterized, aside from its distinguishing color, by being hard and brittle and by its relatively lifeless appearance. [Standard Grading Rules for Northeastern Lumber para. 706.0]

This image shows one example of compression, commonly called a compression failure.